A & C Edwards of Ashby, Massachusetts. No. 116. A composite dial wooden geared tall clock. BBB-2.

This country case is constructed in New England white pine and retains much of its original painted surface. This surface is consistent throughout the case construction and shows some areas of light crazing. The coloring is excellent, and the faux grain pattern is vibrant. The case is supported by an applied bracket base that rests flat on the floor. The base section is compressed and transitions into the center or waist section via a deep cove-shaped molding. The waist section is long and narrow and is fitted with a large rectangular-shaped waist door. This door is trimmed with a simple molded edge. Opening it will provide access to the interior of the case. Here one will find the pendulum and two tin can drive weights. The hood is finished with a cornice top. Fully turned bonnet columns are positioned on each corner of the hood. They are free-standing, and they visually support the upper bonnet molding.

The construction of this arched-shaped dial is interesting. The backplate is tin, and the decorations are applied to it. The front side of this dial plate is painted gold to make it look like brass. The four decorative spandrels are cast in pewter. The design is nicely detailed and is in relief. These are positioned around the outside of the time ring. The two additional cast pewter spandrels are placed in the arch and frame the name boss. They are decorated with human / ghost-like figures. It is my thought that they are positioned in this location to remind us that humans are mortal and that time forever moves forward. This is a reoccurring design on other clocks made by this partnership. A name boss is located in the center of the arch of the dial. This is engraved with the Maker’s name, working location, and the numbering of this clock as 116. The time ring is formatted with Roman-style hour numerals, and Arabic numerals indicate each of the five-minute locations. The seconds registrar is closed. The center mat area is painted gold. This aids in one ability to see the nicely formed hour and minute hands. This clock is also fitted with a calendar. The dial is attached to the movement, with two wooden slats applied to the back of the dial. These are drilled to accept the four wooden dial feet.

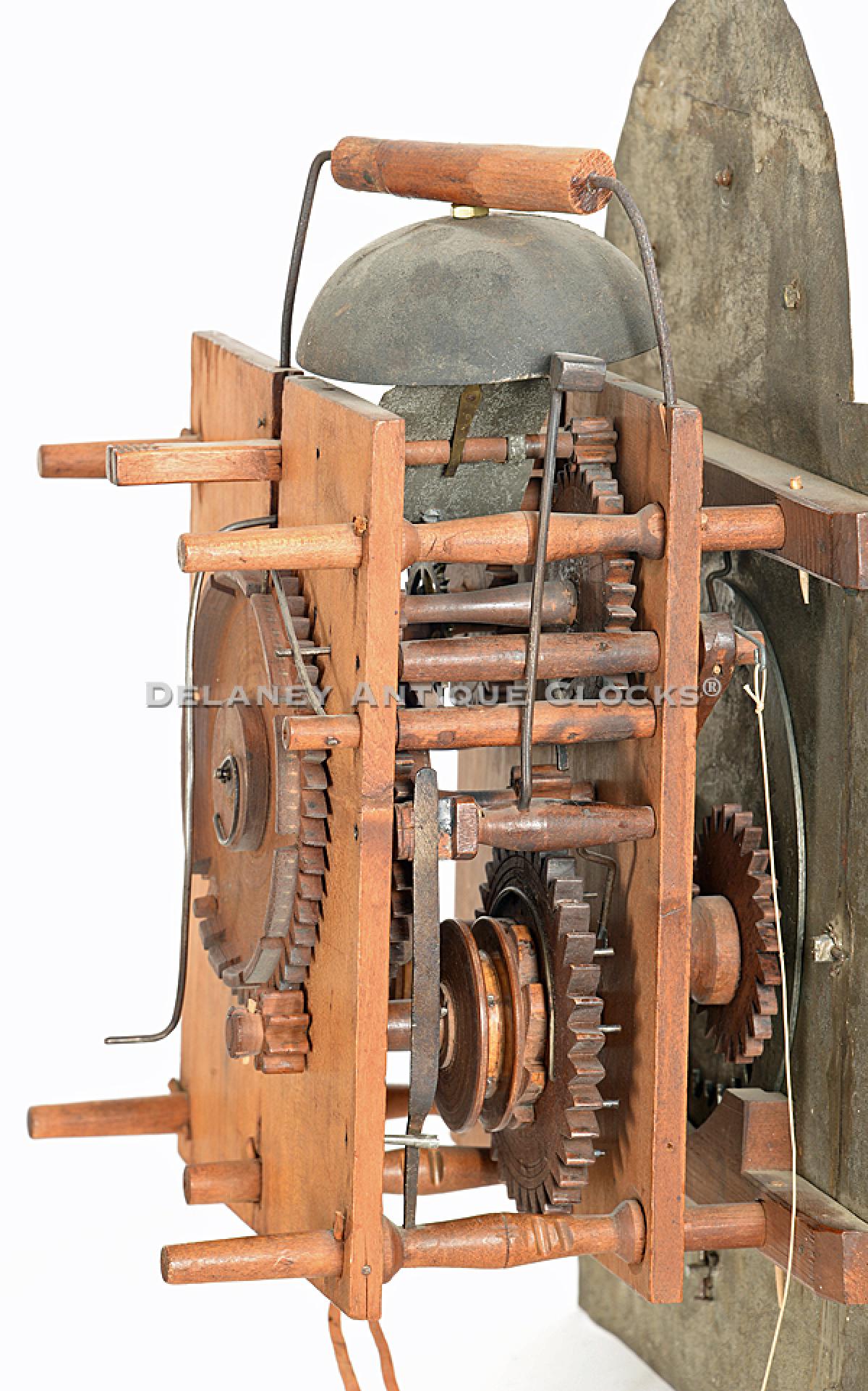

The wooden geared movement is weight powered and designed to run for 30 hours. The winding of this example is done by opening the waist door and pulling a cord that, in turn, raises a weight. Both trains are set up as direct drives. The movement is a time-and-strike design and of fine quality. It features a count wheel striking system that will strike each hour on a cast iron bell. The count wheel is located on the outside of the movement on the back plate. The pendulum rod is wood and supports a lead bob.

This clock was made circa 1790. The overall height of this example is approximately 7 feet 6 inches tall.

Inventory number BBB-2.

Abraham Edwards is believed to have been born in Concord, Massachusetts, in 1761. His younger brother Calvin was born two years later, in 1763. Both were the sons of Samuel Edwards and Huldah Easterbrook of Concord. The family moved from Concord to Ashby, Massachusetts, sometime in 1777. Ashby was then and still is today a small village located in Massachusetts on the New Hampshire border due North of Worcester.

Abraham and Calvin were hard workers and owned everything in common, including several pieces of land in the town of Ashby. They entered a partnership in 1792 and made wooden gear clocks. These clocks are signed on their dials "A & C Edwards." This partnership lasted approximately four short years until Calvin's death at the age of 33. While alive, the collaboration appears to have produced more than 530 clocks. A number of horological references state that their production exceeded 600 clocks, but the highest number that I have personally seen recorded is in the upper 530s. It is assumed that all the clocks made after the partnership ended are signed by Abraham only. Many such examples have been recorded. Early examples of the A&C partnership feature composite metal dials. The later examples, sometime after the number 190, feature the use of a colorfully painted wooden dial.

Abraham and Calvin were responsible for training other clockmakers. Some of these include Abraham's son John and Calvin's sons Calvin Jr. and Samuel. They also trained Alexander, Jacob, and Philander Jacob Willard of Ashburnham. Several members of this Willard family moved to Ashby. A. Eaton, Jonathan Barker, and Samuel Taylor of Worcester. Possibly Bartholomew Ballard from Townsend but worked in Antrim and Temple, NH, and later moved to Ohio. This list of names is still growing.