E. Howard Clock Co four pendulum Isochronal regulator designed by Hezekiah Conant. RR-76.

The E. Howard Clock Company of Boston, MA, manufactured this important clock in 1888 for Hezekiah Conant. The case is dated with a die-stamp inside. The original order has been found in the Howard Company log books, and it indicates that it was ordered on April 3, 1888, and was delivered on November 30 of the same year. Pawtucket, Rhode Island's thread king, Hezekiah Conant, placed the order. Mr. Conant was charged $1,605 for this clock, which was an extraordinary sum. Considering that in 1888, a two-dial tower clock (or public clock) installed in a town meeting house or church steeple cost approximately $400. This is the E. Howard Clock Company's tour de force. Conant was a gifted mechanical designer and received a patent for this very unusual timepiece mechanism on August 23, 1887. This clock features an escapement design that incorporates four individual mercury pendulums. As a result, it is called an "Isochronal clock." The unique design of this clock, with its four pendulums swinging independently and the averaging process, was a significant advancement in clockmaking, leading to increased accuracy and precision.

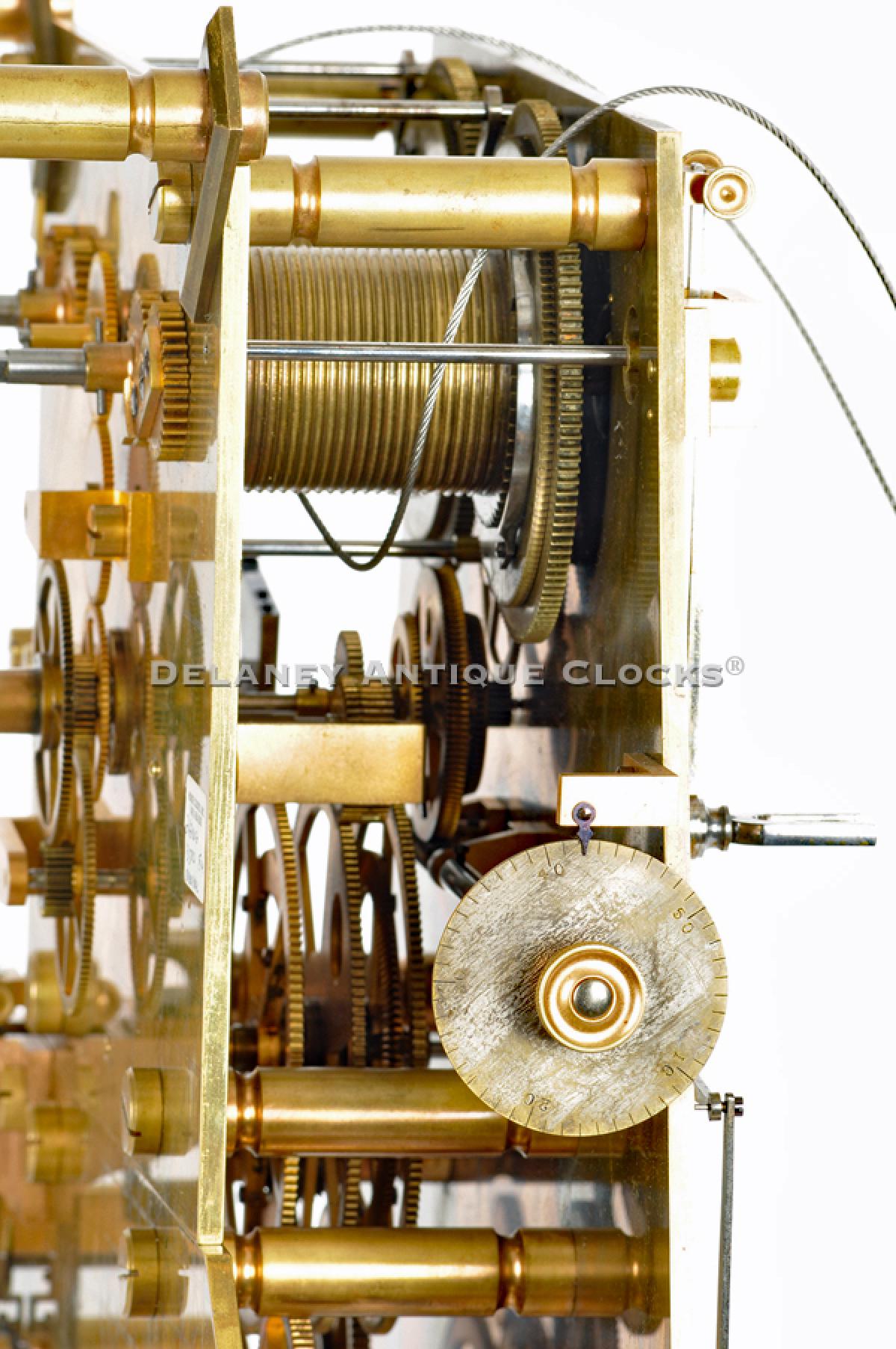

Conant's theory is that four pendulums swinging independently on separate escapements and having a movement that takes their average would be more accurate than a single pendulum clock. Conant claimed that the elimination of error is always in proportion to the square of the number of pendulums. This implies that a two-pendulum clock would reduce the error to one-fourth. Thus, four pendulums would reduce the error to one-sixteenth. The difficulty in this theory is how to take the multiple pendulums and translate their independent impulses mechanically into a single mechanism. This is ingeniously done with a combination of averaging wheels and planetary gears.

The main dial of the clock is formatted in the traditional style. This large dial is divided into twelve hours; Roman-style numerals indicate the hours. Arabic numerals are used to mark the five-minute intervals atop each hour. The individual minutes are marked on the closed time track. This also serves as a seconds ring. Each second would be indicated by the long sweep second-hand mounted from the center arbor. Each pendulum is represented on the dial plate with a subsidiary dial that tracks their progress. Each pendulum features four mercury-filled canisters, and the rods are of different lengths. As a result, each will have a specific number of beats per minute. This clock features pendulums that beat 56, 58, 60, and 62 beats per minute. Each of these dials is marked to indicate at which rate they are tracking. Internally, the dials are geared into pairs, and the averaging process begins. The result is recorded on the two smaller dials above the four individual seconds dials. The gearing is then designed to take these two averages and average them again. This end result is recorded by the sweep second hand on the main dial. European and American Government ships of the time used this averaging process extensively. Many ships were designed to carry multiple chronometers on board. The standard practice was to average their results to give the correct Greenwich time. This aided in the calculation of the vessel's longitude. Conant's first version of this clock was Constructed by Tiffany & Co. in 1887. That clock is said to have had all four pendulums of the same length. As a result, the astronomers of the day believed that the pendulums would synchronize by overpowering each other. This was due to the vibration that would develop in the pendulum's airspace. Conant improved on that clock with this design by moving the weights to their dedicated weight channels and constructing the four pendulums of varying lengths.

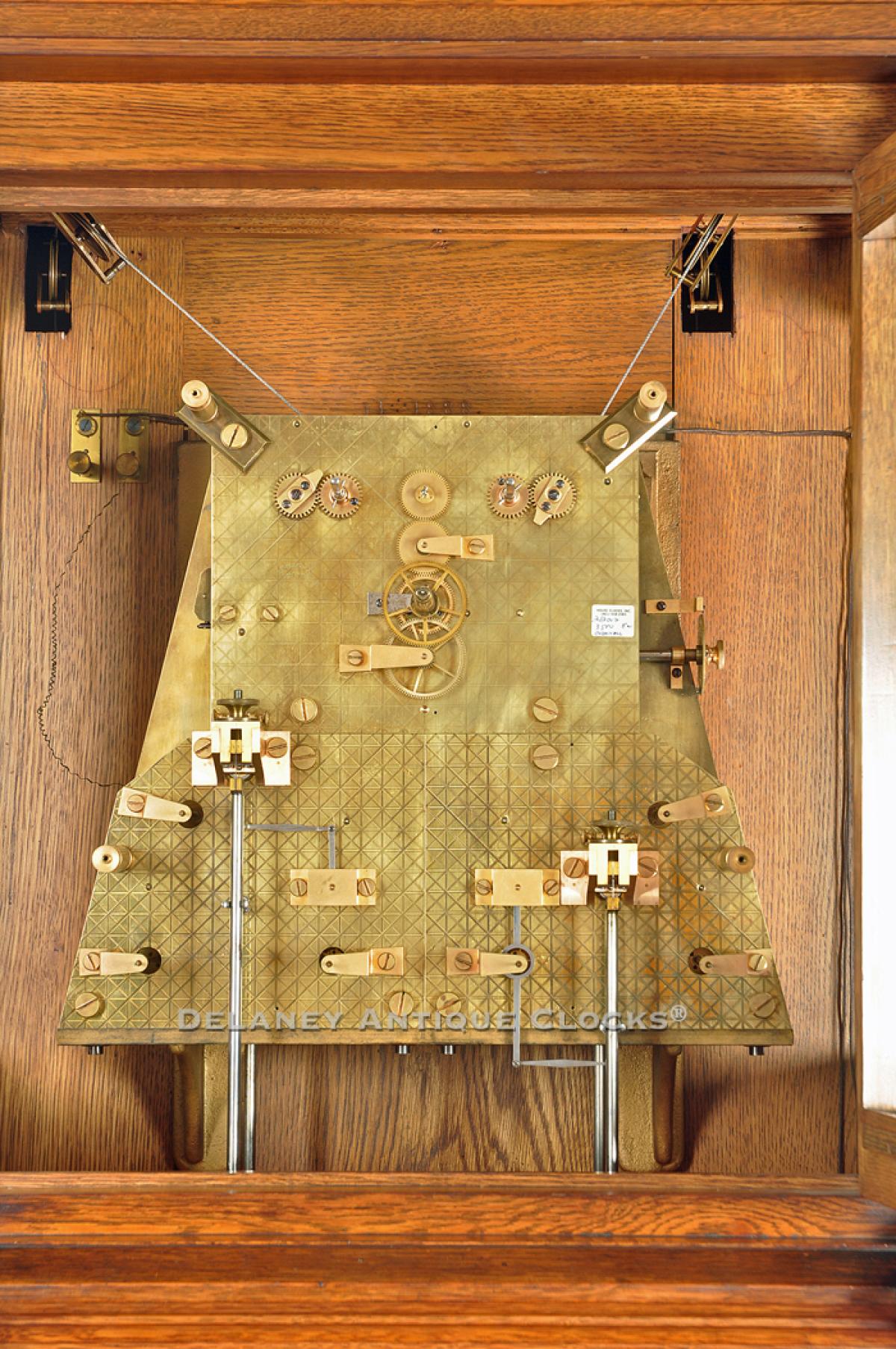

This massive movement is constructed in brass is a testament to the skilled artisans of the time. The framing features a single back plate. Ten large pillars secured with screws support the three separate sections of the front plate. These plates are line decorated, and the upper front plate bears the Maker's die Stamp, "E. Howard & Co. Boston." Five and six-spoke wheels are driven by two large cast iron weights fitted into the cabinet in dedicated weight channels at the back of the case. These are accessible from the sides of the case via doors. The weight cords wind onto grooved barrels at the top of the movement. These are connected to great wheels with stop work and maintaining power. The train is constructed with three sets of planetary wheels designed to carry the power to each of the four deadbeat jeweled pallet escapements. Two pendulums are mounted to the front of the movement, and two are mounted to the large movement mounting bracket at the back of the case. The fine regulation arrangement of the sweep second hand is mounted on the right side of the movement. This allows one to adjust the clock to 100th of a second while the clock is in operation.

This custom-built case is constructed in oak and retains its original old oak finish. The finish is in excellent condition and has developed a warm and inviting tone. It stands approximately 8 feet tall, 34.5 inches wide and 22 inches deep. Two glass doors in the front of the case allow one to access the dial and the four pendulums. Four smaller glass doors on the case's sides allow additional interior access. The bonnet door on the right can also access the sweep second-hand micro adjustment. Four wooden paneled doors on each side of the case provide access to the two large weights. The decorative elements incorporated into the case design include a combination of Art Nouveau and traditional features. The fluted columns are fully turned. All four terminate at the top with carved Corinthian capitals. This impressive clock has a lovely presence.

Hezekiah Conant of Pawtucket, Rhode Island, was a successful mechanical engineer and industrialist. His business, The Conant Thread Company, was one of the great thread mills of the region during the last quarter of the 1800s.

Hezekiah Conant was born in Dudley, Massachusetts, on July 28, 1827. He was the fourth child of Hervey and Dolly (Healy) Conant. Hezekiah attended local schools and paid for his college courses at Nichols Academy in his hometown.

Growing up in rural Dudley, MA, Hezekiah farmed during the summer months and was educated during the winter. At the age of seventeen, he left home for Worcester and entered the printing trade. From there, he moved to work in a local machine shop and became interested in mechanical drawing. He began to study mechanical engineering. He developed extraordinary abilities as a mechanical engineer and inventor. It is reported that sometime around 1852, he invented a pair of "lasting pinchers" for shoemakers. He patented this device but did not profit from it. He worked in various machine shops in Boston and Worcester before traveling to Hartford, Connecticut, where he worked for the gun manufacturers. He works in Colt's firearm manufactory. He also worked for Christian Sharp, the inventor of the Sharp rifle. In 1856, he invented and patented an improvement on the Sharp rifle, known as the "gas check." This was considered so important that the United States and British governments immediately ordered its application to all arms manufactured for them by the Sharp Rifle Co. In the same year, he constructed a machine for Samuel Slater & Sons of Webster, Mass. The machine was used to sew the selvage on doeskins. Conant did not secure this device, but it was very successful and has been used ever since. Mr. Conant soon turned his attention to improving the machinery used in thread manufacturing. He constructed a machine for dressing sewing thread and invented an automatic machine for winding spool cotton. Both of these devices were patented. The Willimantic Linen Co. was so impressed with this new design that they purchased half the patent right and engaged Mr. Conant as a mechanical expert on February 1, 1859. He invented the 'ticketing machine,' which cuts out labels, gums them, and applies them simultaneously to each end of the thread spools at one hundred per minute. In 1864. he traveled to Europe in the interest of his employers and inspected many of the large thread establishments in the old world, among them the great works of J. & P. Coats and of the Messrs. Clark in Paisley, Scotland. When he returned in 1865, he was superintendent of the works of the Willimantic Linen Co. until 1868. During this period, the company doubled its capital and production.

In 1868, Mr. Conant resigned from his position with the Willimantic Linen Co. He moved to Pawtucket, where he organized the Conant Thread Co., with an authorized capital of $100,000 and became the treasurer of the corporation and the manager of the works. During the development period, Mr. Conant has continued to be treasurer and manager. He continued to develop and maintain a relationship with the J. & P. Coats of Paisley, Scotland, the leading thread manufacturer in the world. Conant's business grew to employ over 2000 persons. It is considered one of the best-arranged, best-equipped, and best-organized establishments of its kind in the world. By 1893, the business covered about forty acres of land, and the capital invested exceeded $4,000,000. Good wages have always been paid to the operatives.

E. Conant had additional interests and responsibilities in the region. He served as the president of the Pawtucket Institution for Savings, president and director of the Pacific National Bank, vice-president of the Pawtucket Safe Deposit Co., and director of the First National and Slater National banks of Pawtucket. He was an important patron of Nichols Academy, where he erected new school edifices, dormitories, an astronomical observatory built and equipped, and a fine library and reading room.

Mr. Conant has been married three times. His first wife was Sarah Williams, daughter of Col. Morris and Elizabeth (Eaton) Learned, to whom he was married on October 4, 1853. She died July 17, 1855. In November 1859, he married a sister of his first wife, Harriet Knight Learned, in 1864. On who died July 6 December 5, 1865, he married Mary Eaton, daughter of Dr. Samuel P. and Harriet (Eaton) Knight.

Hezekiah Conant of Pawtucket, Rhode Island, died on January 22, 1902, at the age of 74. He is buried in Corbin Cemetery in Dudley, Mass.

Inventory number RR-76.

The E. Howard & Company succeeded the Howard & Davis firm in 1857. The Howard & Davis firm was comprised of Edward Howard and David Porter Davis and was established in 1842 in Roxbury, Massachusetts. Both men had just completed their clock apprenticeship under the guidance of Aaron Willard Jr in Boston. The Howard & Davis firm made high-grade clocks, precision balances, sewing machines, fire engines, and watches. After the dissolution of Howard & Davis, Edward Howard became Boston's leading manufacturer of weight-driven residential and commercial clocks. The firm also made a large number of tower clocks and watchman and salve clock systems. These sold well in the last quarter of the 1800s.

It has been said that the E. Howard Clock company never made an inexpensive clock, and everything they made was of very good quality. As a result, Howard clocks have become very collectible and are prized by their owners. Today, the E. Howard name enjoys outstanding name recognition.

For a more in-depth reading of Edward Howard and his various businesses, please read "Willard's Patent Time Pieces," written by Paul Foley.