James Fenton, London. Here is a George III inlaid mahogany tall case clock with an arched dial and automated rocking ship display. 223333.

This is a majestic specimen of English clockmaking. The London clockmaker James Fenton made this important longcase clock. Its high-style, fully-developed London case features the automaton of a rocking ship in the arch of the dial. Longcase clocks that combine the mechanics of a working mechanism with added complications, even the simple addition of an automaton, are some of the rarest and most incredible ever made.

Brain Loomes' reference book, Watchmakers & Clockmakers of the World, lists James Fenton. Loomes lists Fenton working in London, England, in the late 18th century. At the time, London had been the leading center of clockmaking for more than half a century. As a result, clocks made there were of the latest style and often of the best quality.

This London-made cabinet is of the highest quality. The base, waist section, and hood are all decorated with figured mahogany veneers and high-quality inlays. The quality of the mahogany selected for the construction of this example is first-rate, and much of it is vibrantly grained. A double-stepped cutout bracket base supports the case. The feet and scrolling apron are shaped from the same board. The base panel features a figured mahogany panel. The panel is decorated with inlaid quarter fans at each corner. The fan blades are sand-shaded, a process that provides visual depth. A satin-wood banded inlay conforms to the shape of the base. This pattern features ovolo corners that set the quarter fans on the outside of the pattern. Lastly, an inlaid oval is centered in the frame. The waist section is long and narrow. The front corners are inset with fluted quarter columns that terminate in fancy brass quarter capitals. The upper capitals are a Corinthian form. The columns and capitals are finished in gold paint. The quarter columns are standing on satin-wood framed mahogany plinths. A break-arch tombstone-shaped waist door provides access to the two brass-covered lead drive weights and the brass-faced pendulum bob inside the case. The applied molding that trims this door is also gilded. It frames the Vauxhall plate glass mirror selected for this location.

The Vauxhall glassworks was located in the Vauxhall area of Lamberth, London, and dates back to 1612. It closed in the 1780s. Mirror glass was costly in the late 17th and early 18th centuries due to heavy taxation and limited production. Glass was also protected from importation. As a result, this company controlled most of the glass supply in England. The use of mirrored Glass in an application like this was considered a sign of affluence.

Above the door are two sunburst inlays constructed with six individual wavy-shaped rays. The double break-arch bonnet or hood is designed with a pagoda top. The center of the pagoda or bell is fitted with an inset cast brass decoration. The casting pattern is pierced and backed in green silk. The sides of the pagoda terminate with fluted moldings that form finial plinths. These are capped with fancy molding, each supporting a brass ball-and-spike finial. The frieze features an additional pierced brass casting. The decoration is floral-themed. This is also framed with fluted moldings. Additional pierced brass castings are mounted in the tombstone-shaped side lights located on the sides of the hood. Flanking the arched formed bonnet door are fluted and gilded bonnet columns. These are mounted in brass capitals. The top two are a Corinthian form. The door features a cross-banded framing and satin-wood banding. The door is fitted with Glass and opens to access the brass dial.

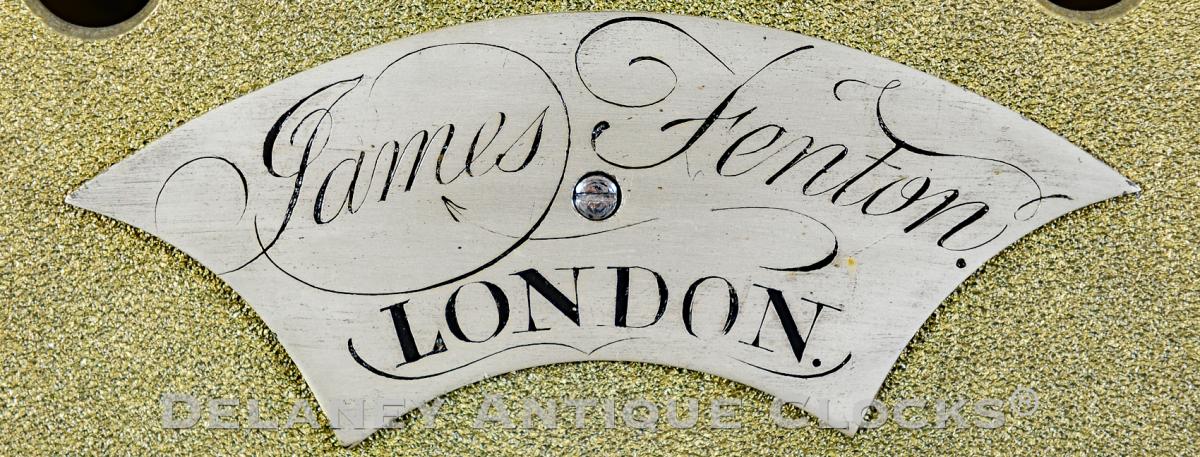

This composite brass dial predates the painted dial form. It is constructed with a brass sheet and is decorated with several decorative elements. Four cast multiple C-scroll corner spandrels frame the applied time ring. The silvered time or chapter ring features Arabic-style five-minute markers, a closed and segmented minute ring, and Roman-style hour numerals. The dial surface inside this ring has been textured or matted. Here, one will find a small square aperture for the calendar day display and an inset subsidiary engraved seconds dial. An applied plaque is located below the center arbor. The plaque is engraved with the Maker's name. This engraved nameplate reads."James Fenton / LONDON." The hour and minute hands are made of steel and are a traditional period form. The lunette surface is decorated with skillful and artful engravings. This frames a painted harbor scene. The turbulent waters are crashing against a fort on the left. A chip in the background is headed into the harbor. A painted automated rocking warship moves or rocks gently from side to side with the pendulum's motion in the foreground. Automated tall clocks are difficult to find. They would have been made as a special request and were more expensive than the standard flat dial form.

The two-train movement is brass, has an eight-day duration, and is good quality. In the London tradition, four turned pillars or posts support the two large cast brass plates. Hardened steel shafts support the polished steel pinions and the brass gearing. The works incorporate a recoil escapement and a rack-and-snail striking arrangement. This clock strikes each hour on a bell mounted above the works. The winding drums are grooved to accept the weight cords in an orderly fashion. Two brass-sleeved weights power all of this. The movement is secured to a wooden seatboard that rests on the rails of the case. The pendulum hangs behind the mechanism from a bridge. A brass-faced lead bob is at the bottom of a metal rod.

This James Fenton cased clock is approximately 102 inches or 8 feet 6 inches tall to the top of the center finial. The bonnet molding is 20.25 inches wide and 9.75 inches deep.

This clock was made circa 1790. English clocks of this quality are a treat to see.

Inventory number 223333.