Seth Thomas. 30-day wall clock. The Hudson. 223160.

This Seth Thomas wall clock is cataloged as the “Hudson,” and it is a variant of their popular Office No. 11 model. The Hudson shares the same brass, thirty-day double-spring powered movement with a Graham dead-beat escapement, seconds display, and Geneva winding stops. Where this model differs is the case presentation.

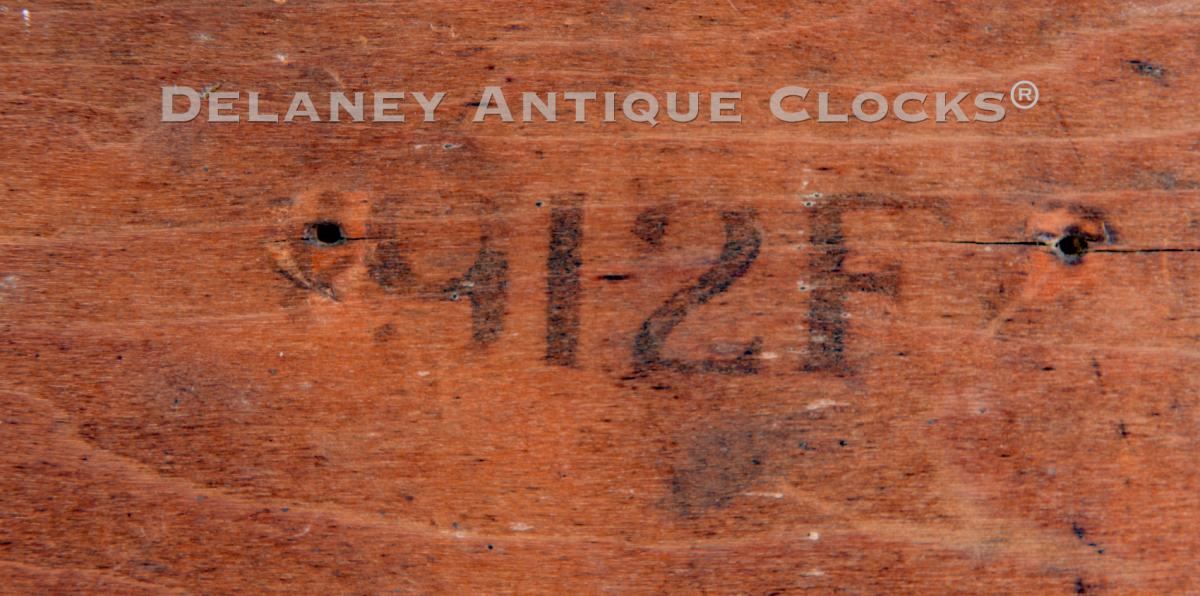

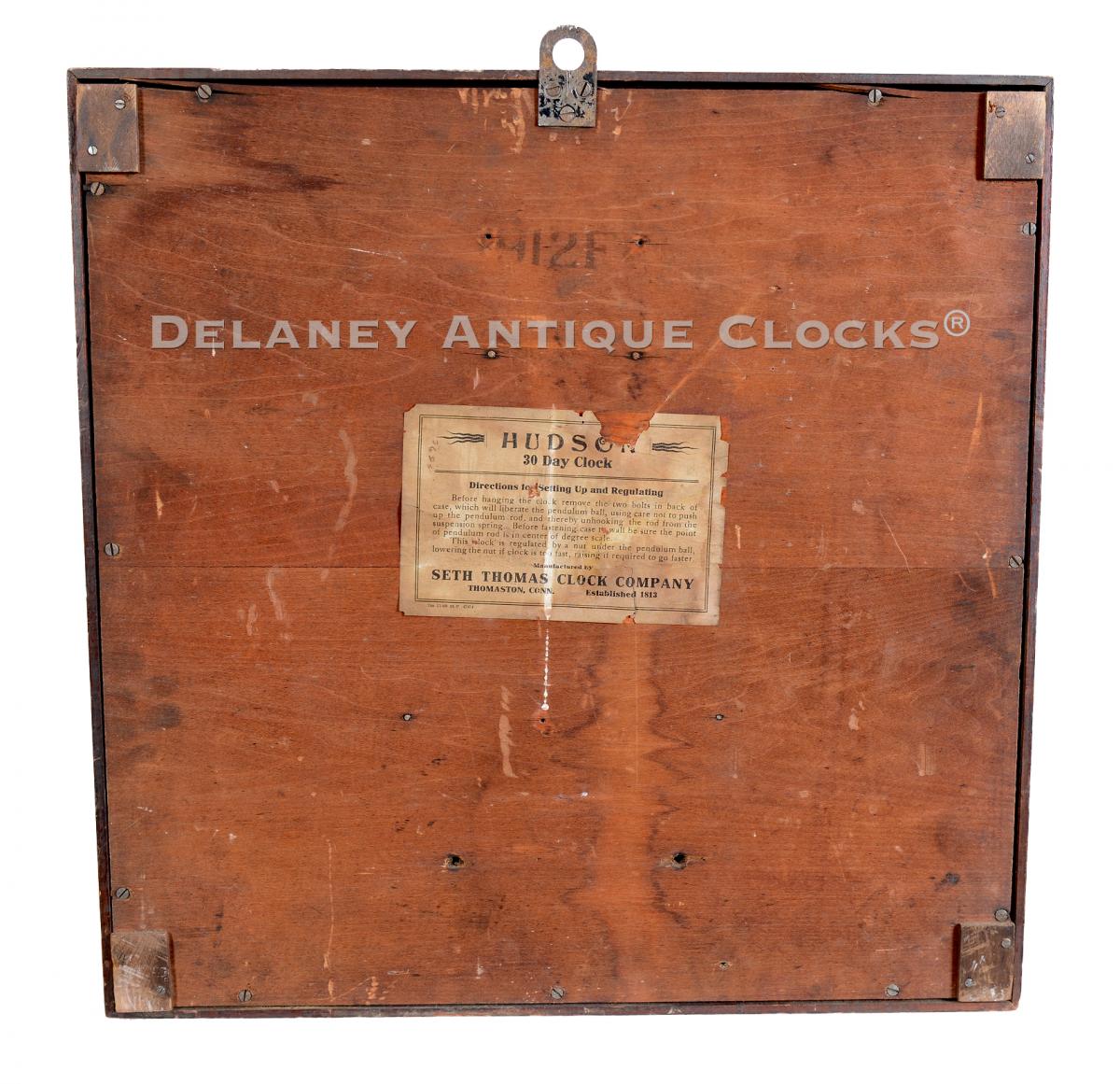

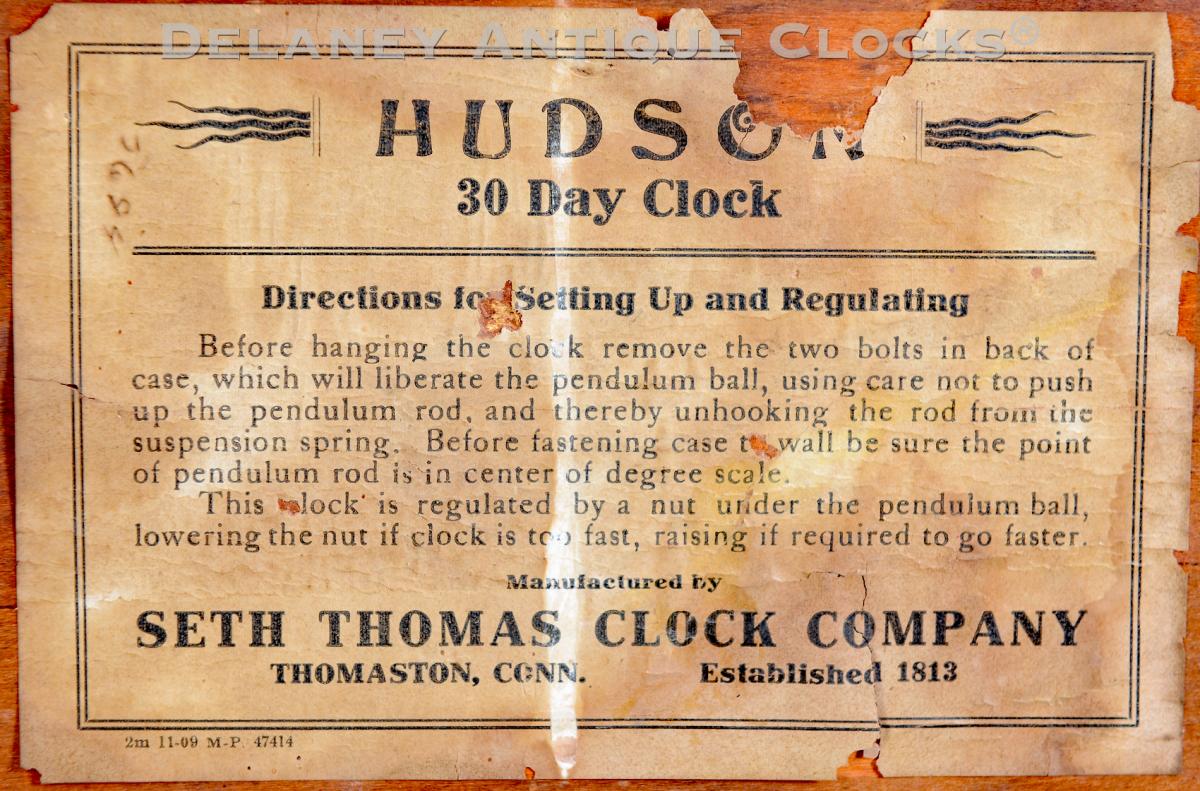

The Hudson features a mahogany case decorated with line inlay and chamfered edges. This outstanding example retains a pleasing finish. The front-facing of the case features miter-style joinery, and the circular aperture that frames the dial is fitted with glass. The glass is held in place with a brass trim ring. This door locks closed with the same key used to wind the mechanism. The Clockmaker’s set-up label is pasted on the back of the case. This clock is also dated in the Seth Thomas date code. It was made in Jun elf 1912.

The 14-inch diameter painted tin dial is in excellent original condition. It features a closed minute ring. The Arabic hour numerals are presented in a tumbled format. A subsidiary seconds dial is located below the hour 12. The Maker’s name, “SETH THOMAS,” is featured across the dial’s center. Under hour 6 is the “MADE IN U.S. A.” statement. Spade-shaped minute and hour hands display the time.

This Hudson case is 18 inches square.

This clock was in June of 1912.

Inventory number 223160.

Seth Thomas was born in Wolcott, Connecticut, in 1785. He was apprenticed as a carpenter and joiner and worked building houses and barns. He started in the clock business in 1807, working for clockmaker Eli Terry. Thomas formed a clock-making partnership in Plymouth, Connecticut, with Eli Terry and Silas Hoadley as Terry, Thomas & Hoadley. In 1810, he bought Terry's clock business, making tall clocks with wooden movements. Seth chose to sell his shares in the partnership in 1812, moving in 1813 to Plymouth Hollow, Connecticut, where he set up a factory to make metal-movement clocks. In 1817, he added shelf and mantel clocks. By the mid-1840s, He successfully transitioned to brass movements and expanded his operations by building a brass rolling mill and a cotton factory. In 1853, He incorporated the business but continued to be the majority shareholder. This clock business expanded until it became one of the "BIG Seven" in Connecticut. Their product line had offerings that competed at every price point, from kitchen clocks to precision regulators. Seth Thomas died in 1859. The community of Plymouth Hollow so revered him that they changed the name on July 6, 1875, to Thomaston in his honor. After his death, his son, Aaron, took over the company's leadership. Aaron is credited with increasing the business by adding a number of new case styles and improving production methods. The company went out of business in the 1980s.