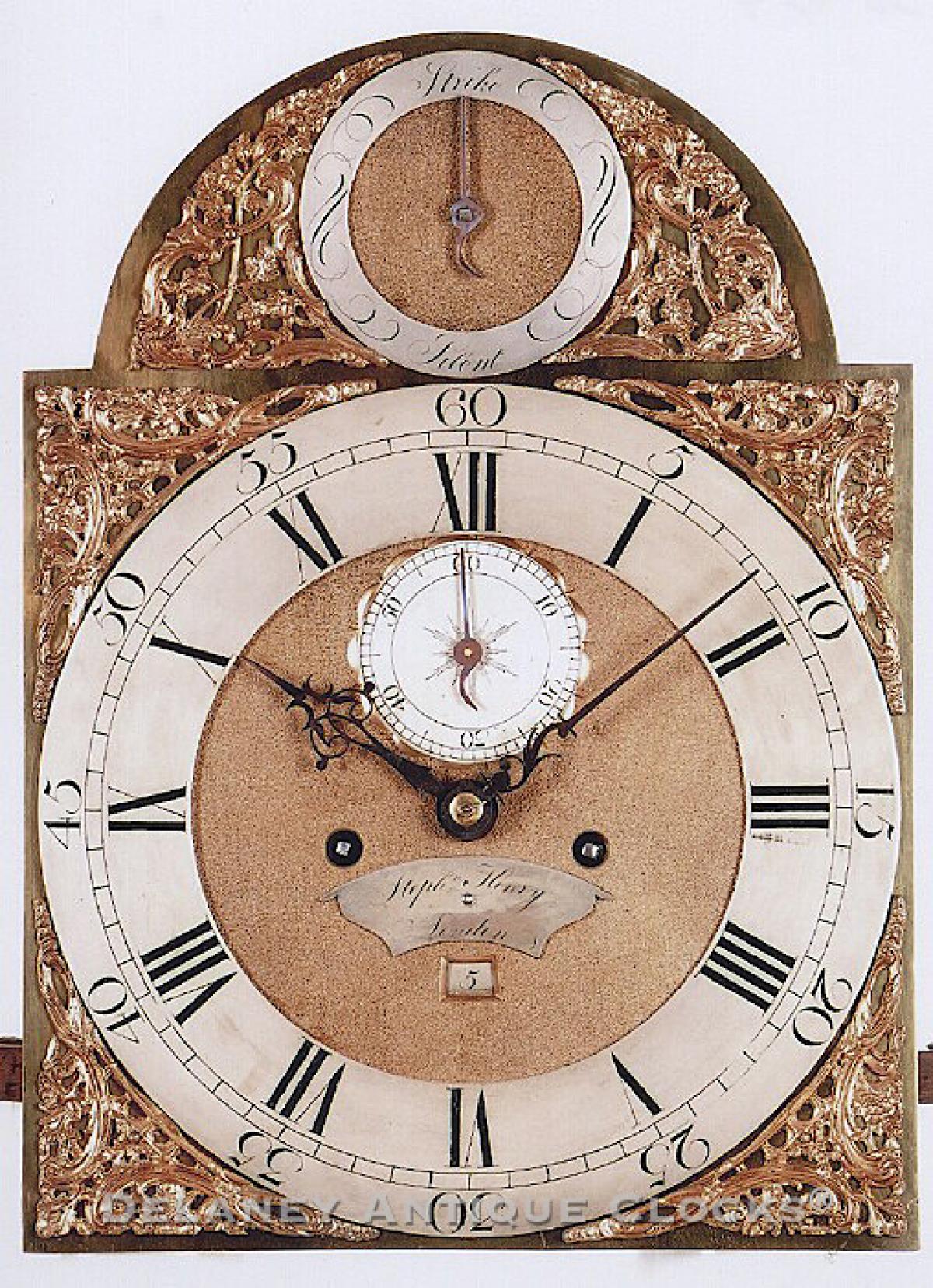

Stephen Henry of London, England. Tall case clock. SS-129.

This impressive long case was made in London. It features a brass dial signed by the London clockmaker. "Stephen Henry" Henry is listed in Brain Loomes Watchmakers & Clockmakers of the World as working in 1760.

Fine high-grade mahogany cases like this one are unmistakably made in London. This pagoda-top example exhibits excellent London proportions. The base stands on an applied double-step molding terminating in thin pad feet. A figured mahogany ovolo-cornered panel is applied to the front of the base. The waist section is long and narrow. It features a large tombstone-shaped waist door. The veneered panel selected for this location is outstanding. The sides of the waist or the corners are fitted with brass stop-fluted quarter columns. These terminate in brass quarter capitals at each end. A bell top or a pagoda form surmounts the bonnet. An inset brass rococo panel is fitted into the front facade. Two brass ball-and-spiked finials are mounted on their respective finial plinths at the hood's outer corners. These plinths are fluted and capped with a wooden molding at the top. The bonnet door is arched and fitted with glass. Fully turned and brass stop fluted bonnet columns ending in brass capitals flank its sides.

This style of brass dial predates the painted dial. Brass dials are very expensive to manufacture. It is constructed with a solid sheet of brass decorated with applied cast brass rococo-style spandrels, an applied chapter ring, and a matted center section. The arch spandrels center a "Strike / Silent" switch. Manually turning this hand will shut off or turn on the striking train of the clock. The time ring displays the five-minute makers in Arabic figures and Roman-style hours. An applied subsidiary seconds dial is located in the traditional location. Interestingly, it features Arabic figures at five-minute intervals. This dial is signed by the Clockmaker on an applied plaque within the time ring between 3:30 and 8:30. The engraved signature and working location are in script lettering. The middle section of the dial is matted. This treatment aided one in locating the hands while reading the dial. A brass dial in the 1700's could quickly tarnish. Living conditions were much dirtier during this period. A tarnished dial may be difficult to read in rooms heated by coal and lit by candle or oil light. This clock was made long before electricity and central heat were a homeowner's options. Today, dials like this keep their contrasting for generations because the household environment is so much cleaner. As a result, the wonderfully made steel hands are easier to locate and read.

The movement is constructed in brass, having nicely finished cast brass plates supported by ring-turned brass posts. The gearing is brass, and the pinions are steel. The weight-driven movement is designed to run for eight days on a full wind. This clock strikes the hour on a bell. The strike train is located between the plates and is actuated by a rack and snail design. The winding barrels are grooved. A seatboard supports the movement inside the case. The pendulum features a metal rod and a brass-faced lead bob.

This clock was made circa 1775.

It measures 7 feet 9 inches tall.

Inventory number SS-129.