William Bond & Sons - Boston. A floor standing astronomical regulator made circa 1865. 219008

This high-quality precision regulator was specifically built for Francis Blake (1850-1913) of Weston, Massachusetts. This Bond clock is a first-class timekeeper and, in its day, was one of the finest available. Mr. Blake was a curious gentleman and an inventor. He was trained as a physicist and worked on the United States Coast Survey for 12 years. He had at his home a first-class laboratory and an observatory where he studied the various things that interested him. Some of these discoveries were patented. Blake's most successful patent related to a microphone. This patent was used by Alexander Graham Bell in his telephone.

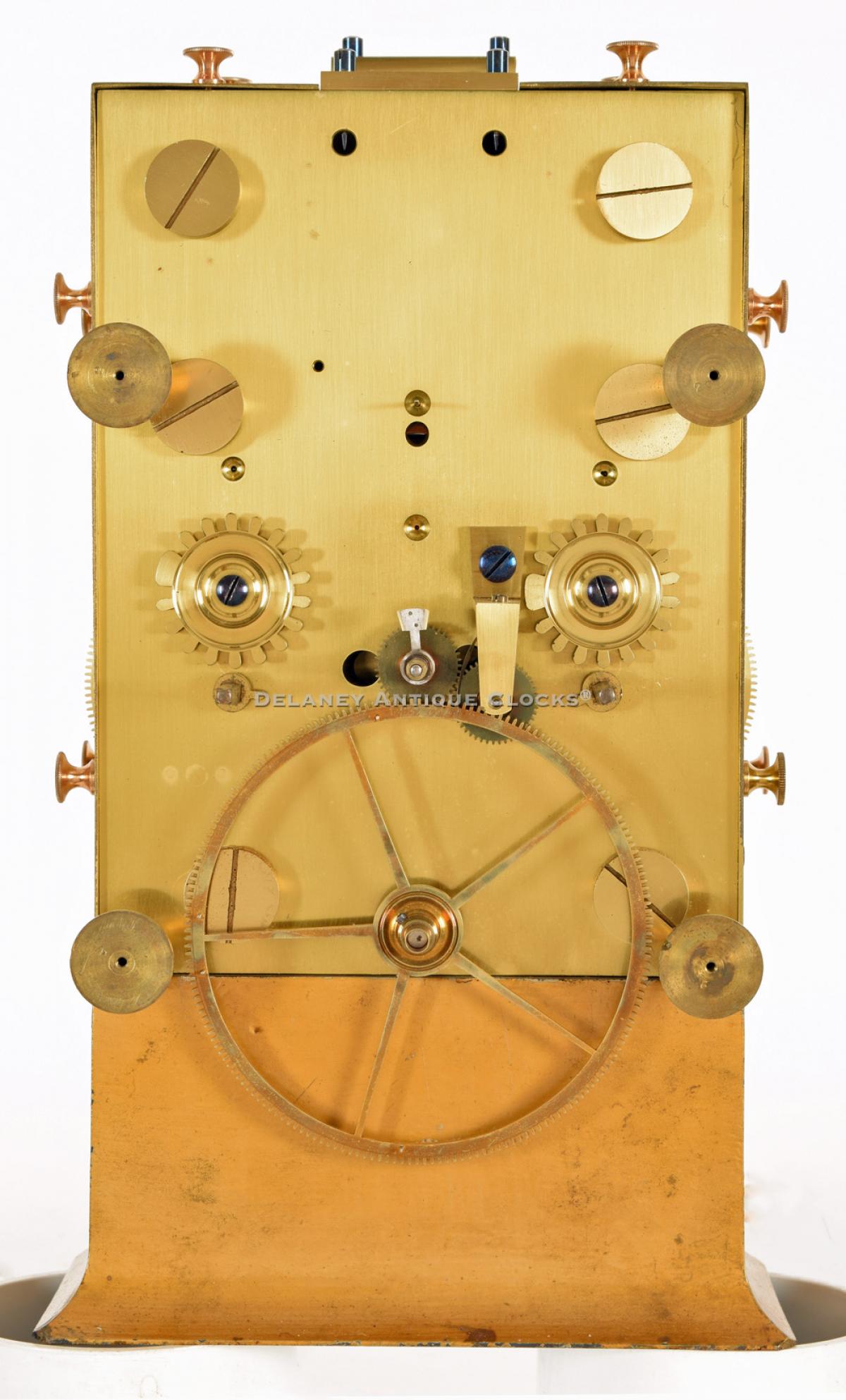

There are a number of variables that affect the timekeeping ability of any clock. True regulators are designed and constructed in such a manner as to compensate for or minimize the effects of these. The design and construction of a regulator movement are critical. This movement is heavily constructed. Two heavy cast rectangular-shaped brass plates provide the frame. These are fastened together with six large brass posts. These are screwed tight from both ends providing rock-solid stability. Brass dust plates or covers are fitted to the three sides. These are secured with six individual thumb screws. They provide an extra layer of protection from air-born particles such as dust. The hardened steel shafts are fitted into the holes drilled in the plates. The pivot holes are reportedly fitted with jewels on the inside surfaces. A jewel's surface is very hard, and this hardness prolongs the life of the bearing. Without jewels in this location, the circular brass holes would wear more quickly into an oval shape causing the clock to suffer in performance. These shafts are also equipped with pinions. These are designed to match up very well with the brass constructed gearing. The gearing in this mechanism is lightly constructed, taking into consideration the effects of mass and friction. The gearing is mathematically calculated to provide the optimum performance throughout the train. Fitted inside the movement is a two-second break circuit. This would send an electrical impulse to a chronograph. This system was used in observatory settings.

In 1860, there were three options to power a clock. Electricity was still in its development stages and was often unreliable. As a result, it was not a suitable option for a precision clock. Spring power was quite common and used extensively in clocks of all shapes and sizes. The problem with spring power is that it is variable. A spring clock has more force when it is fully wound than that of a spring that is nearing the end of its power cycle. This power difference can greatly affect a clock's rate. The third option is weight power. Weights are constant. A clock powered by an eight-pound weight at the top of the wind is also powered by an eight-pound weight at the bottom of the wind. The power derived from a drive weight is also linear. The great wheels or power wheels on this clock are grooved and are designed to accept the cord that supports the two unusually shaped weights. This clock requires two weights to drive the gearing, escapement, and pendulum for eight days.

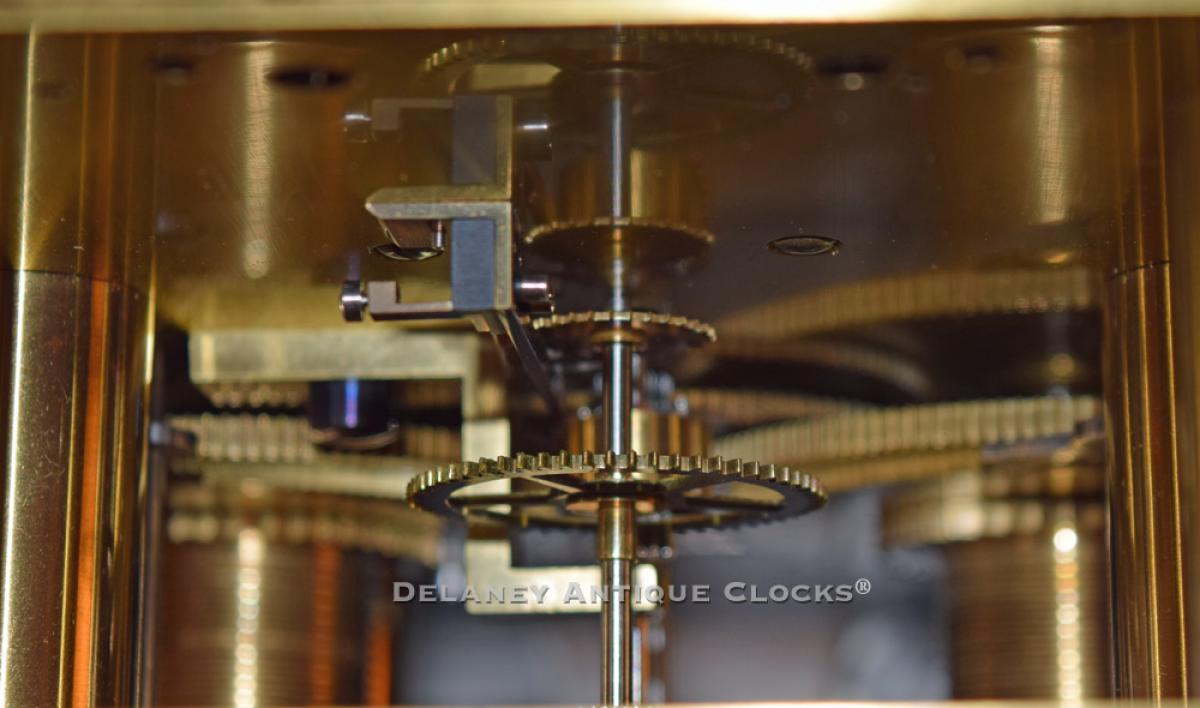

The two weights used on this clock are unique to Bond. They are in the form of orbs, and a center grove is cut into it along its circumference. The weight cord travels along this groove. As a result, a pulley is not required. The transfer of power or the effect of gravity on the weights moves the energy up through the gear train to the escapement, which ultimately powers the pendulum swing. Both of the great wheels are fitted with maintaining or retaining power. Maintaining power is a feature that provides power to the train while the clock is in the process of being wound. This prevents the power loss that is experienced while the clock is being wound. The result is that it continues to keep time while being wound. The pendulum and the escapement regulate the rate of the clock in symphony. This regulator is fitted with a Denison gravity escapement which was new and advanced technology for the day.

In 1850, Edmund Denison developed an escapement specifically for the clock known as Big Ben in London. This escapement is designed so that the train of the clock does not act directly on the pendulum. This escapement lifts a small weighted arm off the pendulum at the end of its impulse. The arm is lifted and then released again, providing an impulse to the pendulum. This process is timed to precise and particular moments. When released, the arm's weight is powered by gravity alone and thus delivers a consistent impulse. The bond clock uses two gravity arms on opposing sides of the pendulum. They are raised by pins that extend from the six-legged wheel. These pins interact with the roller disks fitted to the arms' ends to minimize friction. Denison's escapement was the most advanced development in this technology when this clock was built. This escapement is located at the back of the movement and is put on view for all to witness.

The pendulum is carried or supported by a heavy brass bracket that is mounted to the top of the movement. A nicely shaped cradle locks the pendulum into place. The pendulum features a steel rod that supports a single metal jar. This jar holds a volume of mercury that is calculated to compensate for the effects of temperature on the length of the rod. A threaded nut is used for fine regulation.

This brass dial is engraved in an astronomical dial format having individual dials for the seconds, minutes, and hour display. Please note that all of the numerals are in an Arabic form. The hour dial displays the time in a 24-hour format. This suggests that this clock was originally used for sidereal time, the time of the cosmos. This dial is engraved with the Marker's name across the middle. It reads, "WM. BOND & SON - BOSTON." This brass dial is finished with a silver wash. This provides a stark contrast between it and the engraved details and the three-blued steel hands.

The case.

The movement and dial are enclosed in a rectangular case that features large rectangular glass panels on five sides. This provides another level of protection from airborne particles. The design also allows one to view the clock from all sides. The front glass panel is drilled in the two winding arbor locations. This allows the clock to be wound without having to remove the top. The holes are sealed with plugs that are fronted by silver and backed by cork. This top section sits above the case, which is made in two sections.

A regulator needs to be very stable. Wall versions provide heavy brackets for the movement and pendulum to be mounted to. Floor regulators are often very stable, and great care is used in setting them in place. Many of the most accurate clocks were mounted on plinths or piers that extended from the bottom of the clock down to bedrock. Some of these were installed so that they were independent of the building's walls and floors in an attempt to isolate them from the vibration of the building. This clock features a masonry case. The case is made in Blanco Carrara marble which is often considered a symbol of quality and distinction. This product was quarried from the Alpine region of Italy and would have to be imported into this country. It is very heavy. The base alone weighs approximately 450 pounds. This was to ensure that the clock stayed in place. The middle section is hollow. Here, a space is provided for the two weights and for the motion of the pendulum to swing freely. The front section of this waist is fitted with a glass door. The weights and pendulum are visible as a result. Below the pendulum is a beat scale. This scale is well formed and engraved with the company's name.

Inventory number 219008.