A lovely inlaid cherry case tall clock made by Timothy Chandler of Concord, New Hampshire, circa 1805. This clock is signed on the dial by the Maker. 219140.

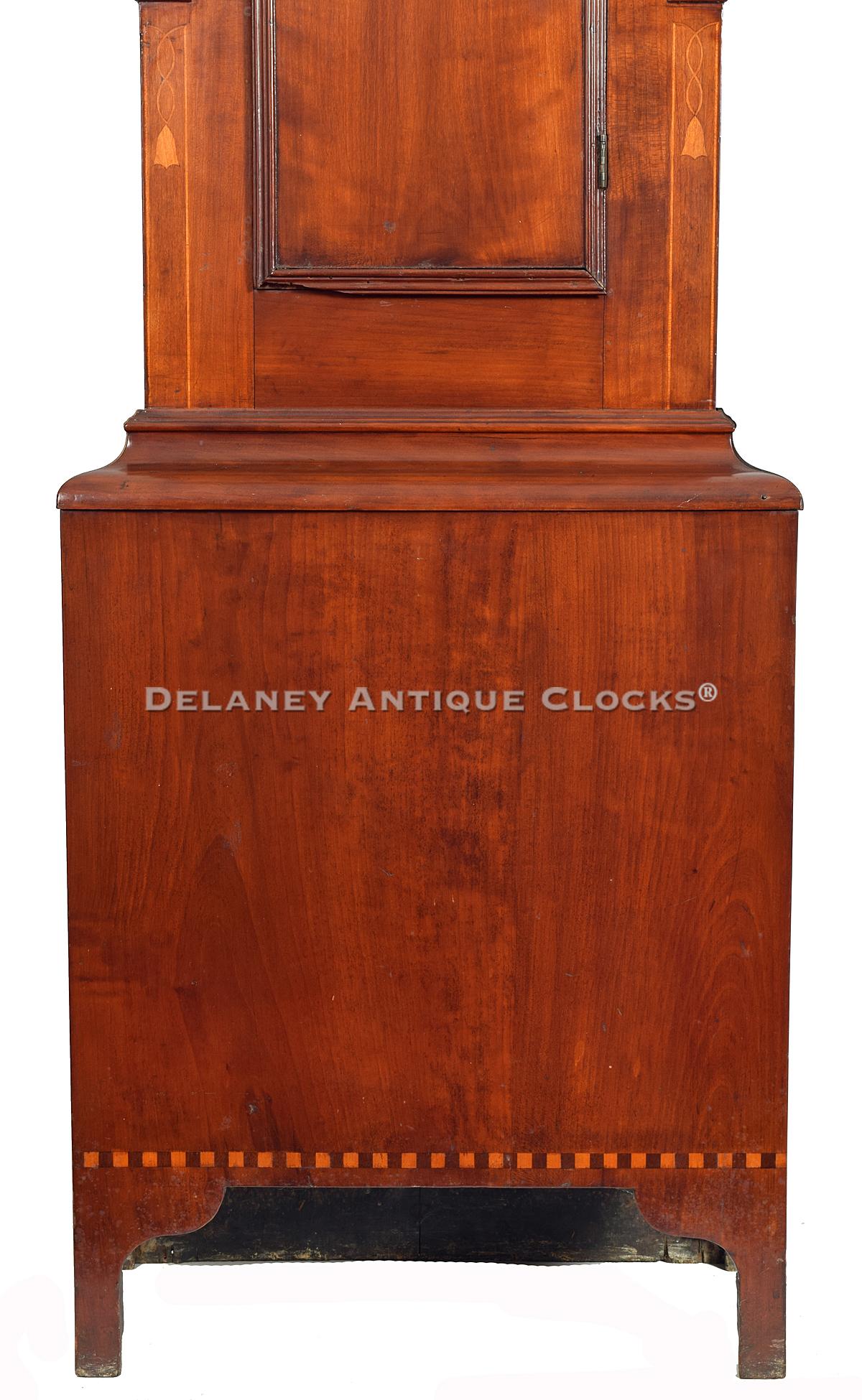

The case is constructed in woods found locally in the central New Hampshire region. The primary wood is cherry, and the secondary wood is New England white pine. The line inlays are most likely holly. This case has been appropriately refinished in the last 50 years. The pleasing color accentuates the grain of the wood, which is quite lively for cherry.

This fine example stands up on four feet. They are cut out of the base section and retain excellent height. The cutout design between the feet forms a subtle return before crossing straight across the bottom of the base panels. This section is visually divided from the base by a line of inlay. The pattern consists of a small block of light and dark wood positioned in an alternating pattern. This line begins at the back of one side, continues across the front panel, and ends at the back of the opposite side. The waist section is fitted with a rectangular-shaped waist door. This is trimmed with an applied molding. Through this door, one can access the interior of the case, and the components include the drive weights and the brass-faced pendulum bob. Additional inlay patterns are located in the blocks that support the quarter columns. This pattern consists of a line that turns across the back and crosses over itself to form a pendant. Below this is a bellflower inlay. Reeded quarter columns are mounted in the corners of the waist and are secured at each end in brass quarter columns. The bonnet or hood features a pierced and open fretwork pattern. This decorative detail is a traditional New England design. It is supported by three inlaid finial plinths. Each plinth is fitted with a brass ball and spike finial. The molded arch is supported by smoothly turned bonnet columns. These are free-standing and mounted in brass capitals. These flank the arched bonnet door, which is fitted with glass. Rectangular-shaped side lights are located on both sides of the hood.

The painted iron dial is a locally made product. It was painted by the Boston ornamental artist Spencer Nolen. The front of the dial is signed by the Clockmaker, "Tim Chandler / Concord," in script lettering. The location of the signature is positioned just below the month calendar aperture and is now somewhat faded. In the arch of this dial, one will find a moon phase mechanism or lunar calendar. The lunar calendar or moon phase mechanism is a mechanical almanac. This feature was most likely made on special order due to the extra work involved in producing it. This display would have been valuable to several occupations during the colonial era. Farmers were known to track the moon phase to anticipate the days that offered the most available moonlight. A bright night would be more beneficial to them in scheduling the tilling and harvesting of their fields. Sailors and merchants track the lunar phases to know when the high tide would allow their ships to sail easily from a port or when the fishing might be best. Numerous religious groups had an almost superstitious litany of rituals that were best performed in accordance with lunar events. The actual lunar month represents an inconvenient interval of 29 days, 12 hours, 44 minutes, and 2.8 seconds. A tall clock's lunar calendar is set constant at 29.5 days, which represents a full cycle. As a result, a 9-hour setback is required at the end of a single year to keep the lunar display current. The four spandrel areas are decorated with colorful floral patterns. A gilt ring frames the outer edge of the time ring. Small Arabic-style numerals are used to mark the quarter hours. A minute ring is used to separate the quarter hours from the Hours. Each of the twelve hours is presented in large Roman-style numerals. A subsidiary seconds dial is located just below the hour XII.

The clockworks are constructed in brass and are of good quality. Four turned brass pillars support the two brass plates. Hardened steel shafts support the polished steel pinions and brass gearing. The winding drums are grooved. The escapement is designed in a recoil format. The weight-driven movement is designed to run for eight days on a full wind. It is a two-train or a time-and-strike design, having a rack and snail striking system. As a result, it will strike each hour on the hour. This is done on a cast iron bell, which is mounted above the movement.

This beautiful clock was made circa 1810. It stands approximately 7 feet 9 inches tall to the top of the center finial.

Inventory number 219140.

Major Timothy Chandler was born on April 25th, 1762, in Rumford, Maine, and died on July 22nd, 1848, in Concord, NH. He is the son of Timothy and Elizabeth (Copp) Chandler and was one of five children. His father died when he was eight years old, and it has been suggested that Timothy traveled to Pomfret, Connecticut, in 1770-1783 to serve an apprenticeship to Jonathan Hale, who was a wool card maker. It is not known who specifically taught him the art of clockmaking. It is speculated that Chandler may have also trained as a clockmaker with Peregrine White, who was at work in nearby Woodstock. (Timothy named one of his sons Peregrine White Chandler.) Timothy moved back to Concord in 1791 and advertised tall clocks for sale. He was also appointed Sealer of Weights and Measures in Concord, NH. It is reported that in November of 1787, Timothy married Sarah Abbott of Concord. This suggests that he must have traveled back and forth to Concord from Pomfret before he settled there. Together they had twelve children.

In Concord, Timothy became a prolific clockmaker until his retirement in 1829. His main competition was Levi and his brother Abel Hutchins. Timothy was responsible for training several clockmakers, including his sons, Timothy Jay, John Bradley, and Abel. It has been suggested that he trained Joseph Chadwick in about 1801, who was from Boscawen. He also apprenticed Deacon Cyrus Eastman of Amherst, NH. Eastman served a seven-year apprenticeship which ended about 1814.

In 1797, Timothy enlisted with the Minute Men and received the commission of Major in 1799. He also served as vice president and then the president of the Merrimack Agricultural Society in the early 1800s. In 1808, he was appointed the Surveyor of Highways in Concord. On the evening of August 17th, 1809, he suffered a fire that originated from his air furnace or forge in his clock manufactory. The manufactory, with all its contents, the house, the barn full of hay, and two other hay barns were lost at a value of $5,000. Interestingly, the citizens of Concord raised $1,200 in order to help offset his losses and to rebuild. Chandler would rebuild and continue his career as a clockmaker.

In 1814, when Governor Gilman ordered the creation of local companies to defend the town in the event of an attack, Chandler, now in his 50s, again volunteered to serve in the militia. In 1819, he served as Chairman of the first "Lancastrian School." In 1820, he and his son Timothy Jay formed a partnership as T. Chandler & Son. This partnership lasted four years until T. Chandler & Co was formed in 1824 and lasted until 1828. This second company also included Timothy Jay.

In 1825, Timothy Chandler was one of the nine officers of the newly formed New Hampshire Mutual Fire Insurance Company, one of New Hampshire's earliest fire insurance providers. In 1827, he served as Chairman of the group that organized the Unitarian Society. From 1829 through 1830, he joined his son Abel under the firm name of A. Chandler & Co. After 1830, he worked alone, served as President of Concord's first Temperance Society, was Vice President of Concord Mechanics Association, and was one of 17 original trustees of the N.H. Savings Bank. In 1834, he named three of Concord's streets.

We have owned numerous examples of his work. These include tall clocks, timepieces, mirror clocks, and shelf clocks. A fair number of silver items are also known.